Site: Orjol (Russia)

Volume flow: 30 000 m³N / h

Burner power: 3 500 kW

Purpose: Exhaust air purification for production of vinyl flooring

Dimensions TNV: 12 800 x 3 891 x 4 047 mm (LxWxH)

Weight: 30 279 kg

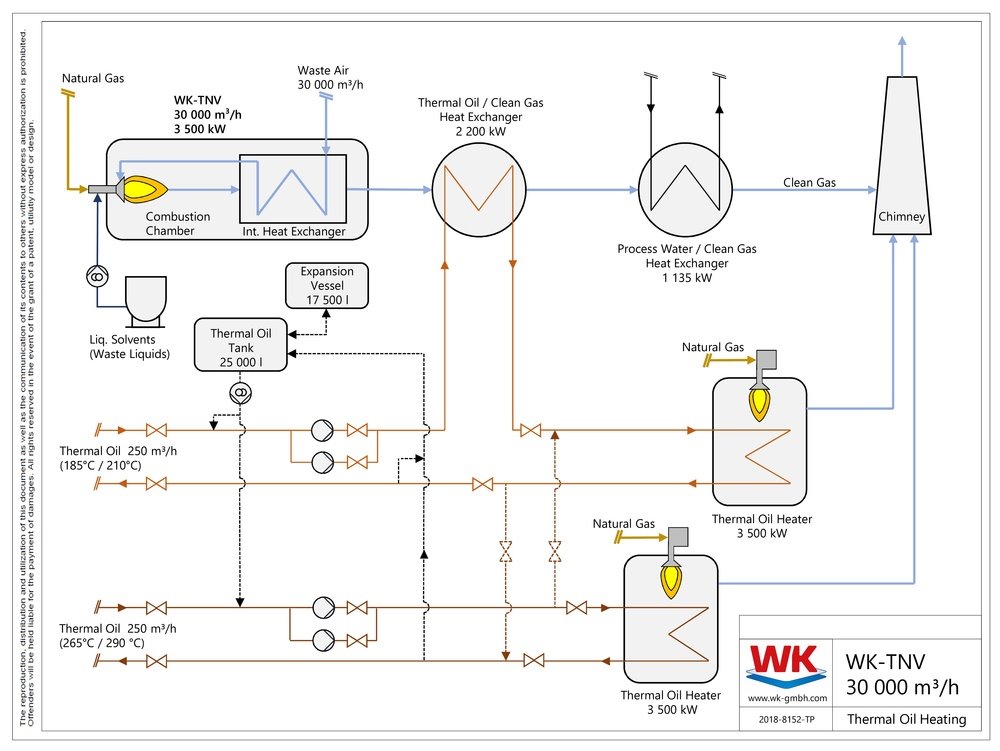

The VOCs contained in the process exhaust air from producing vinyl flooring are incinerated in the TNV (Thermal Oxidizer) and thereby rendered harmless. In order to recover the resulting heat energy from the clean gas, a thermal oil heat exchanger (2 200 kW) and a water heat exchanger (1 135 kW) are connected to the TNV.

The thermal oil circuit consists of a high-temperature and low-temperature circuit, each with its own pump station. In the low-temperature circuit (LT), the heat exchanger pre-heats the thermal oil before it is heated to 210 °C in a separate thermal oil heater (3 500 kW). In the high-temperature circuit (HT), the thermal oil is heated by another thermal oil heater (3 500 kW) to a total of 290 °C. Since the high-temperature circuit has priority, the thermal oil can be bypassed to the LT thermal oil heater in case the HT thermal oil heater has to be serviced.

For the volumetric expansion of the heated thermal oil, an expansion tank of 17 500l is used, which is connected to a 25 000l foot vessel.

The TNV has the option of burning additional liquified solvent, which is formed as a waste product during production. The solvent is sprayed directly into the combustion chamber with a solvent lance.