Ovens, dryer and cooling zones are essential in every coating process. For environmental protection and to comply with the legal emissions limiting values we consequently minimize the use of primal energy. That’s why our efficient and durable TNV or RTO systems are the perfect addition for our ovens. Of course all relevant system components can be produced by WK‘s own production in Wetzlar (Germany).

Features:

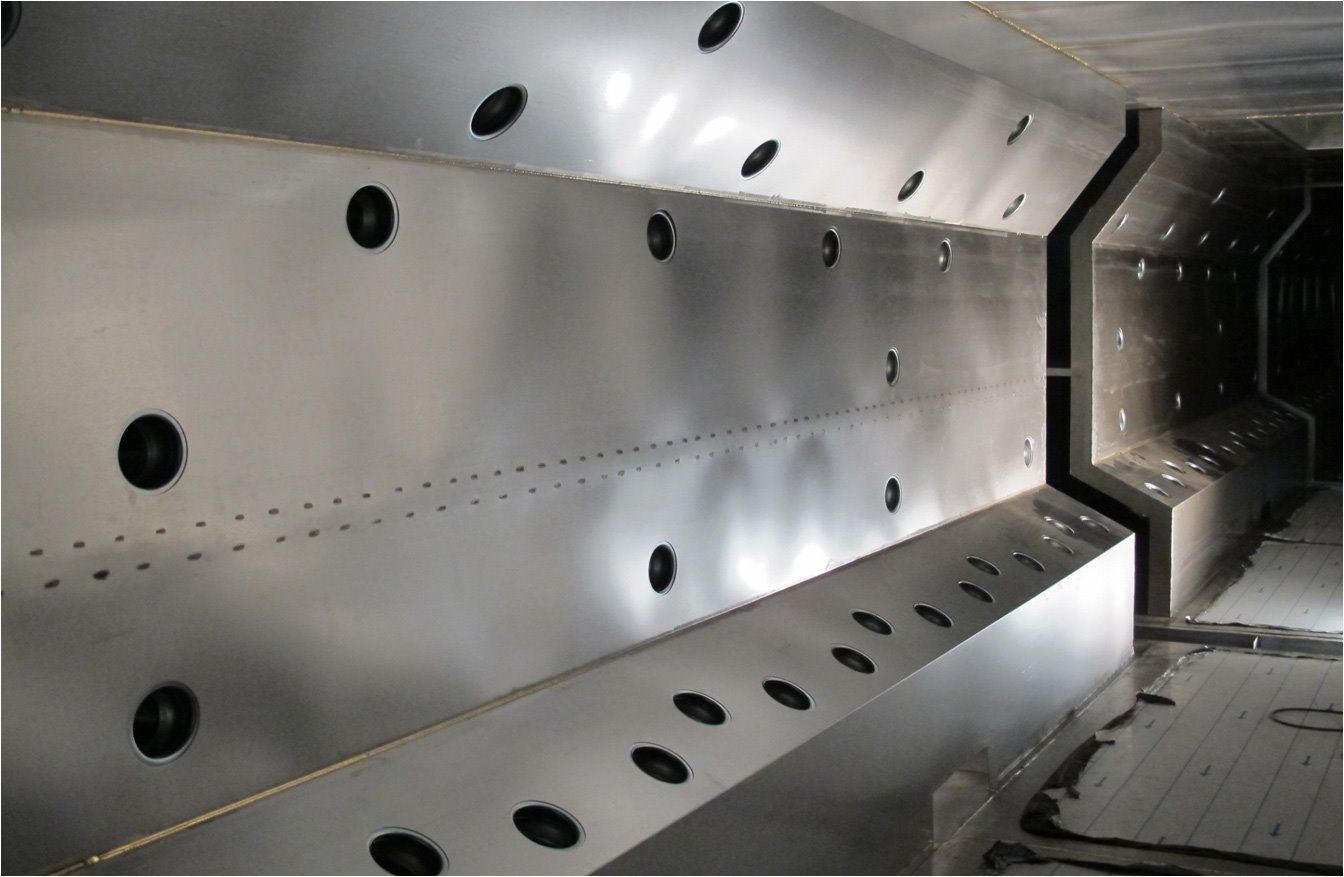

- Convection ovens, directly and indirectly fired by gas burners or thermal incineration system

- Plastic ovens for flared flange (dryer for raw bodies)

- Infrared dryers

- Water dryers, directly or indirectly fired

- Hardening ovens for aluminum parts

- Tempering ovens for plastic parts

- Chamber ovens for small parts